A few days ago, the electro-hydraulic fat-injection pump developed by the third section of the oil production management of the No. 2 Oil production Plant of Northwest Oilfield has been successfully tested and applied in 38 wells. The pump is small in volume and convenient and fast. At present, it is being popularized and applied in the whole plant. shaft sleeve

Oil well oil production tree valve fat-filling work is to ensure that the valve can play its normal function, extend the valve service life, reduce the valve leakage or leakage events. It is an important job to ensure safe production of oil and gas wells, oil wells are injected at least once every six months.

In the past, using manual hydraulic fat-injection pump to inject grease, it took 15 minutes to finish the grease injection of a single valve in the oil production tree, which was time-consuming and laborious, wasted labor cost, and also affected the production efficiency.

The newly developed electro-hydraulic grease injection pump in the oil production management area is an independent hydraulic power device composed of a quantitative piston pump, a control valve, a fuel tank, a motor and an instrument. shaft sleeve

The pump has the characteristics of small volume, convenient and fast, high production time limit and so on. In the early stage, the oil production management area has been successfully tested and applied in 38 wells. At present, the oil recovery management area has been successfully used. The electro-hydraulic fat-injection pump is being popularized throughout the plant. According to the fat-filling workload of 795 wells in the whole plant, the single valve takes 15 minutes from the original fat-injection time, which is reduced to only 5 minutes to be completed now. Compared with manual hydraulic grease injection pump, labor cost can be reduced by one million two hundred and seventy-two thousand yuan per year. shaft sleeve

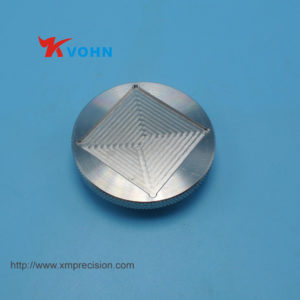

CNC Machining Service & CNC Machining parts

Polishing Carbon steel and die steel alloy steel parts

Plasma surface treatment prototype