In the process of continuous improvement, we repeatedly asked why we could not be fooled by the appearance and find the real root cause of the problem, so as to truly find a targeted solution. cnc machining services china

After the Second World War, Japan’s Toyota Motor Co., Ltd. was once in a very dangerous situation, and its annual car sales fell to 3,275 units.

Car sales did not go out, workers started to strike, and for quite a long time, Toyota was almost on the verge of bankruptcy. Not only is there a shortage of funds, but it is also facing a shortage of raw materials, and the productivity of the Japanese automobile manufacturing industry is very different from that of the United States. cnc machining services china

In front of such a grim reality, Toyota Kiichiro proposed to reduce costs and eliminate unnecessary waste. Use three years to catch up with the United States! Otherwise, the Japanese automobile industry will be difficult to sustain!

In order to realize the ambitions and imminent goals of entrepreneurs, Yono Noda, vice president of Toyota Motor Corporation, thought at night: Why is the productivity of the United States several times higher than that of Japan? There must be a lot of waste in Japan! How can we find a better way of production? Through careful and meticulous research on the production site, a rigorous and mature “just-in-time production” system was eventually formed, which affected the “Toyota production method” of the world. cnc machining services china

The core approach of Toyota’s production approach is to “require the necessary products and complete the necessary quantities at the lowest cost at the necessary time.”

In order to achieve this goal, we must continue to improve. In the process of improvement, the “five why” analysis method is often used to solve practical problems.

Before doing the “five why” analyses, you need to clarify what the problem is and use Toyota’s terminology to “find the situation.”

To find out the situation, we must observe the situation with an open mind and start by comparing the actual situation with the standard. Then, make a preliminary analysis of the cause of the problem. Where is the problem found? This will take you back to the source and approach the root cause of the problem. Subsequently, the results can be found through the “five why” analysis. cnc machining services china

For example, if a machine does not rotate, you have to ask:

“Why did the machine stop?”

“Because of the overload, the fuse is broken.”

“Why is it overloaded?”

“Because the bearing part is not sufficiently lubricated.”

“Why not enough lubrication?”

“Because the lubricating pump is not oiling.” cnc machining services china

“Why not suck on oil?”

“Because the oil pump shaft is worn out, it is loose.”

“Why is it worn out?”

“Because there is no filter installed, iron chips are mixed in.”

Repeatedly questioning the above 5 “why” will find that the filter needs to be installed. And if “why” doesn’t ask in the end, put it on the fuse or replace the oil pump shaft, then the same failure will happen again in a few months. cnc machining services china

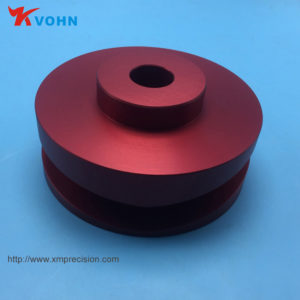

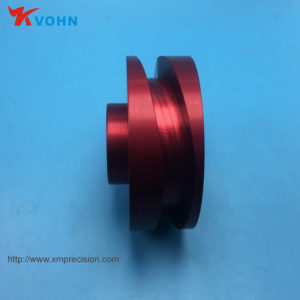

CNC Machining Service & CNC Machining parts

SGS Approved large machining companies Manufacturer

aluminum cnc machine

aluminum cnc parts